Frequently Asked Questions

You got questions? Don’t worry, we’ve answered some Frequently Asked Questions below so you don’t need to ask us and wait for reply!

Coupling selection

Why AWELTA?

Coupling selection

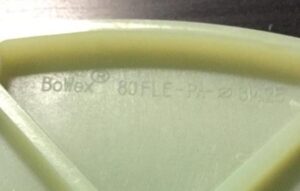

KTR BoWex FLE-PA flange identification

Method 1: Using Description

The most straightforward approach to identifying a Bowex FLE-PA flange is by examining its description. The description typically follows a standard format:

BoWex -> Size (48, 55, 65, 70, 80, 100, or 125) -> FLE-PA -> Coupling Diameter

For instance, “BoWex 80 FLE-PA – 314,25 denotes a Bowex FLE-PA flange with a size of 80 and a coupling diameter of 314,25. Diameter of 314,25 also can be described as SAE 10

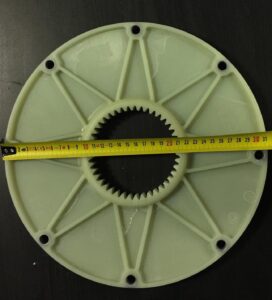

Method 2: Counting Internal Teeth and diameter

If the description is unavailable or unclear, counting the internal teeth is an effective alternative. Bowex FLE-PA flanges have a specific number of internal teeth corresponding to their size:

- BoWex 48 FLE-PA: 50 internal teet

- BoWex 55 FLE-PA: 47 internal teeth

- BoWex 65 FLE-PA: 42 internal teeth

- BoWex 70 FLE-PA: 50 internal teeth

- BoWex 80 FLE-PA: 46 internal teeth

- BoWex 100 FLE-PA: 48 internal teeth

- BoWex 125 FLE-PA: 54 internal teeth

- In case the description is missing, or the flange is broken, count the internal teeth on the hub, which will have the same number of teeth. Additionally, measure the following features:

- Coupling Diameter: Measure the diameter of the flange to determine its size.

- Bolt Pattern: Examine the bolt pattern for flywheel fitment. This pattern is unique for each flange size.

- Bolt Size: If available, measure the bolt size.

Additional Notes

- The material designation “>PA6-GF25<” does not aid in identifying the flange size or type.

- By providing this information when requesting a quote, AWELTA can accurately identify and select the appropriate Bowex FLE-PA

KTR BoWex FLE-PA flange identification

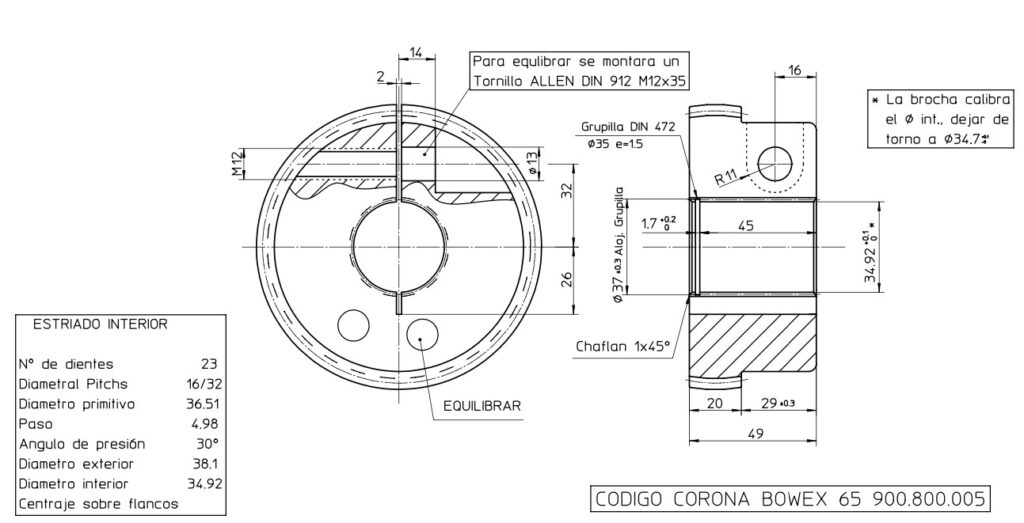

KTR BoWex Hubs identification

Accurately identifying Bowex FLE-PA hubs is essential for ensuring proper coupling selection and compatibility. While photos really help to recognize, dimensions play a crucial role in identifying the correct hub.

Method 1: Using Description

When a description is available, it often follows a standard format:

KTR BoWex 42 PB-S or KTR BoWex 42 PB-BS, BoWex T80 etc.

Method 2: Having Drawing or Drawing Number

If you can provide a drawing, drawing number, or KTR product number, consult the corresponding documentation or reference materials to determine the hub specifications.

Method 3: Identifying Plain Hubs

For plain hubs without any markings, rely on physical dimensions:

- Outer Teeth Count: Count the number of teeth on the outer circumference of the hub. This helps determine the hub size, similar to the flange’s inner teeth count.

- Inner Teeth Count: Count the number of teeth on the inner circumference of the hub. Some hub teeth may be cut out, so counting the teeth on the shaft, if available, is helpful.

- Shaft Diameter or Inner Hub Diameter: Measure either the shaft diameter or the inner hub diameter to determine the hub size.

- Hub Length: Measure the overall length of the hub to ensure compatibility with the coupling and application.

Method 4: Measuring Bore Diameter:

For hubs without a sleeve, measure the bore diameter to determine the hub size and select the appropriate coupling.

By gathering this information, AWELTA can effectively preselect the appropriate Bowex FLE-PA hub for you. Most likely we have this hub in stock or can get it in several days.

KTR BoWex Hubs identification

KTR BoWex Elastic identification

Method 1: Examining Element Description

The element description provides crucial information for identification:

For example – BoWex-Elastic 48 HE 6 1/2

- BoWex-Elastic: Identifies the manufacturer and product type.

- 48: Represents the element size

- HE: Denotes the Highly Elastic type.

- 6 1/2: Indicates the diameter or standard of SAE fitment.

- Available element sizes

Checking Shore Hardness

The shore hardness sticker on the front side of the element provides insights into its softness and performance. Usually it is:

Method 2: Analyzing Photos and Dimensions, inner teeth number of the element

Visual inspection and dimensional measurements can aid in identifying elements when descriptions or markings are unavailable:

- Photos: Clear images of the element from different angles can reveal distinguishing features.

- Dimensions: Measuring key dimensions, such as diameter, length, and hub size, can help narrow down the identification options.

- The number of internal teeth on the coupling element helps to identify the correct size standard of the BoWex-Elastic element.

By combining these methods, you can effectively identify Bowex Elastic HE elements and ensure proper selection for your application.

KTR BoWex Elastic identification

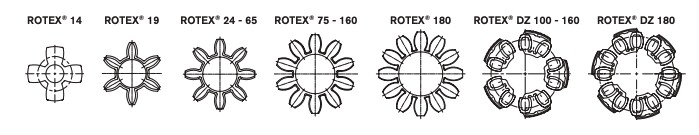

KTR Rotex spiders identification

Visual Inspection:

- Color: ROTEX spider elements come in three colors:

Dimensional Measurements:

In addition to visual inspection, you can also identify ROTEX spider elements based on their dimensions.

Old colors before T-PUR®

64 Shore D – Polyurethane (PUR) – Colour: white -> 64 Shore D T-PUR® light green

92 Shore A – Polyurethane (PUR) – Colour: yellow -> 92 Shore A T-PUR® Orange

98 Shore A – Polyurethane (PUR) – Colour: red -> 98 Shore A T-PUR® lilac

Benefits of T-PUR®

- Longer service life

- Extended temperature range of more than 40 %

- Maintaining all technical properties

- Same price as the traditional spiders

KTR Rotex spiders identification

Centaflex A coupling identification

Centaflex A couplings are relatively straightforward to identify. The main identifying information can be found directly on the coupling element:

Size: The size of the coupling element is typically stamped or embossed on the element itself. This information is crucial for ensuring compatibility with the shafts and power transmission requirements of the application.

Shore Hardness: The shore hardness of the rubber element, indicating its flexibility and damping characteristics, is also typically marked on the element. This information helps determine the coupling’s suitability for various applications with varying misalignment and vibration levels.

Fitment Type: Centaflex A coupling elements come in two main fitment types:

Type 0: This type utilizes screws for secure attachment to the flywheel or hub.

Type 0-S: This type employs pins for secure attachment to the flywheel or hub.

By examining these identifying features on the coupling element, along with the coupling’s overall dimensions, you can effectively determine the appropriate type of coupling for your specific application.

There are other additional codes on the coupling, which help to identify that you have Centaflex A coupling, but they don’t help to identify correct size and fitment, so if you found codes D.B.P. – 2019608 and JAP.Pat. – 778322, Mikki Pulley all good, but you should search for another part of the coupling.

Centaflex A coupling identification

Centaflex K coupling identification

Centaflex K couplings are usually clear to specify. A full description of the flange is usually seen on the spare part.

If the part is damaged – another option is to check the dimensions.

Outer dimensions can be taken from Flywheel – usually it is according to SAE standards.

Inner information can be identified counting metal jaws on the hub:

Centaflex K 100 have 4 pcs of steel jaws on hub

Centaflex K 125 have 6 pcs of steel jaws on hub

Centaflex K 150 have 8 pcs of steel jaws on hub

Centaflex K 200 have 12 pcs of steel jaws on the hub

Identifying Centaflex K hubs needs information about spline, hub dimensions.

If you can provide a drawing, drawing number, photos, or any dimensions of the hub – it helps to preselect hubs correctly.

Centaflex K coupling identification

Centaflex H coupling identification

Centaflex H couplings usually consist of plastic element and aluminum inserts. In most cases it is enough to replace only plastic element. If there are damaged aluminum inserts, they can be replaced as well.

Centaflex H code for identification can be found on the element.

Centaflex H coupling identification

Centaflex X coupling identification

Centamax coupling idendification

To identify correctly Centamax element there are several possible options.

Method 1: Using Description or drawing number

- You may find complete description or drawing number from documentation of your machinery.

Method 2: Visual identification

- Element size – usually seen on element – Centamax 1200; Centamax 5000 etc..

- Element hub fitment described as SC or SCE elements. Usually elements have plain holes for fitment (Type SC), but in some cases there is also additional threaded holes (Type SCE)

- Shore hardness of element, which describe element stiffness and performance parameters

- Element colour – which can be black for Natural rubber (NR) element or bright yellow for silicone (SI) elements.

Centamax coupling idendification

Other couplings identification

Send us a quick inquiry, and attach photos of the coupling, provide dimensions if possible, and throw in the machinery model for good measure. The more details, the merrier! Our experts will dive into the specifics to crack the code and find the perfect match for you. We may help you with Vulkan, Reich, Rexnord, Flender, Stromag, Twindisc.

Why to use original Centaflex or KTR couplings Over Replacements?

At AWELTA, we understand the importance of making informed choices for your machinery. Here’s why opting for original parts like Centaflex and KTR is a superior solution:

Engineered in precision:

Our original parts, such as Centaflex and KTR, are meticulously developed in collaboration with machinery producers. They mirror the exact specifications of the components initially installed during the machine’s production. Every element is carefully selected by engineers, based on thorough calculations and a deep understanding of the machinery’s design.

Original parts ensure peak performance. They are designed to function seamlessly with your machinery, offering unparalleled efficiency and reliability. In contrast, replacements may compromise on precision and often fall short of the high standards set by the original equipment manufacturer.

Efficiency Matters:

While original parts might have a slightly higher upfront cost, consider the true cost of using replacements. Replacing original parts often requires significant time and effort, potentially involving the disassembly of engines or pumps. Couplings, especially in hard-to-reach places, can escalate the challenge. The machine downtime during replacement is a critical factor to consider. Original parts not only minimize downtime but also eliminate the need for frequent replacements, making them a more cost-effective choice in the long run.

Consider the broader perspective—your machinery is a substantial investment, often costing tens of thousands of EUR. It’s the driving force behind your business growth. Why entertain the idea of saving a mere 50 or 100 EUR when it poses the risk of encountering downtime in the not-so-distant future?

Real Numbers Tell the Story:

It’s not just about the price of the part; it’s about the comprehensive cost analysis. Factor in the downtime, labor, and team efforts required for replacement, especially if the replacement isn’t readily available locally. When you put these numbers on the table, the true value of original parts becomes evident. They offer not just reliability but also long-term cost savings and peace of mind.

Choose original parts for your machinery—because investing in quality today ensures efficiency, reliability, and substantial savings in the long run.

Why did your coupling fail?

In certain machinery setups, couplings are intentionally designed to act as sacrificial elements. Their purpose is to absorb excessive loads and unexpected stress, preventing damage to more critical components like engines or hydraulic pumps. The rubber elements within these couplings also play a crucial role by absorbing vibrations and preventing resonance, which can be destructive. So, if you’ve experienced a coupling failure, consider it a sign that the system is doing its job. This deliberate failure actually safeguards your machinery, potentially saving you from costly repairs down the line. It’s all part of the ingenious design to ensure the longevity and health of your equipment. Embrace the concept of sacrificial couplings—they quietly work to preserve your machinery’s well-being!

To ensure the optimal lifetime of your coupling, we recommend proactive maintenance. Check the condition of other components in the driveline, ensuring they are in good working order. Additionally, inspect the alignment of the entire drive line to prevent unnecessary stress on the coupling. Engine pads are another crucial factor; any damage or excessive movement of the engine may contribute to coupling failure. Regular assessments of these elements contribute to a robust and reliable system, allowing your coupling to continue its vital role in protecting your machinery. Remember, a little maintenance goes a long way in ensuring the longevity of your entire system.

Warranties

OE products supplied by us come with a producer warranty, reflecting the high standards of quality and meticulous testing during production. While our commitment to excellence aims to minimize claims, we acknowledge that, in large-scale production, occasional issues may arise. We are fully prepared to review and address each claim on an individual basis, working collaboratively to find satisfactory resolutions. It’s important to note that coupling failures often signal underlying issues in other driveline components. Therefore, claims are exclusive and subject to agreement on both sides, ensuring a fair and comprehensive resolution process. Your satisfaction is our priority, and we are dedicated to providing reliable and efficient solutions for your machinery.

Why AWELTA?

In Stock Guarantee

At AWELTA, we empathize with the urgency that comes with machinery downtime. We recognize that when your machines are down, Every moment is crucial. waiting for entire supply chain to be fulfilled it not an option. That’s why our commitment to you goes beyond just having an extensive stock capacity—it’s about understanding your immediate needs.

Our shelves are not merely stocked; they’re a reflection of our dedication to your operational efficiency. We maintain a diverse inventory, anticipating the urgency for original spares. When every minute counts, our variety ensures that your demands during these critical times are met promptly. Trust AWELTA to be your reliable partner, responding swiftly to your need for fast-acting solutions.

Shipping Options

At AWELTA, we offer more than just delivery options; we provide a tailored experience. Consider our express shipping – it might seem an investment at first glance, but when you factor in the potential cost of machine downtime, it transforms into a highly efficient solution. We understand that time is money, and swift delivery can be the key to minimizing disruptions.

On the flip side, our reliable standard option isn’t just about cost; it’s about cost-effectiveness. If time permits and urgency isn’t the essence of your order, our economy shipment provides a sensible balance between affordability and efficiency. It’s not just about choices; it’s about ensuring your decision aligns perfectly with your unique requirements.

Timely Dispatch Commitment

At AWELTA, we deeply value your time, and our commitment to efficiency is evident in our order dispatch process. For orders placed before 13:00 (GMT+2 time zone), you can count on 100% same-day dispatch. We understand that in your world, every minute counts, and our swift response ensures your orders are on their way promptly.

Even if your order is placed after 13:00, rest assured that our dedicated team puts forth substantial efforts. We strive to dispatch these orders on the same day, and if circumstances require, they will be shipped the very next working day. Your satisfaction is paramount, and our dedication to timely order processing reflects our commitment to your operational success.

Seamless Worldwide Delivery

At AWELTA, we redefine the concept of distance, making it a non-issue for your deliveries. Our commitment to worldwide delivery transcends borders, ensuring your goods reach you no matter where you are on the globe. Distance is not a barrier; it’s an opportunity for us to showcase our expansive reach.

Partnering with trusted names in the industry, such as UPS, DHL, TNT, and FedEx, we extend our delivery network to virtually every corner of the world. This collaboration guarantees that your goods are in safe hands, whether they’re destined for bustling urban centers or remote locations. Experience the convenience and reliability of our worldwide shipping, where borders are mere lines on the map, and your satisfaction knows no limits.

Warranties

OE products supplied by us come with a producer warranty, reflecting the high standards of quality and meticulous testing during production. While our commitment to excellence aims to minimize claims, we acknowledge that, in large-scale production, occasional issues may arise. We are fully prepared to review and address each claim on an individual basis, working collaboratively to find satisfactory resolutions. It’s important to note that coupling failures often signal underlying issues in other driveline components. Therefore, claims are exclusive and subject to agreement on both sides, ensuring a fair and comprehensive resolution process. Your satisfaction is our priority, and we are dedicated to providing reliable and efficient solutions for your machinery.

Exclusive B2B benefits!

At AWELTA, we prioritize your business success. By registering on our platform, you unlock exclusive benefits tailored to enhance your experience:

Priority Support:

Our dedicated support team is at your service, ensuring your queries and concerns receive swift attention and resolution.

Priority Shipments:

As a registered member, enjoy priority in dispatch, ensuring your orders are on the fast track to their destination.

Exclusive Pricing and Negotiable Delivery Conditions:

Access pricing options exclusive to our registered partners, with the flexibility to negotiate delivery conditions that align with your business requirements. After registering at our system – we will contact you by email or phone to identify and agree the best way and conditions of cooperation ensuring your needs and expectations.

Stock Capacity:

Benefit from our extensive stock capacity, ensuring a consistent and reliable supply of products to meet your demands. Centaflex and KTR couplings are ready to be shipped anywhere needed.

Long-Term Trust and Success:

We are committed to building a lasting partnership with you. Trust is the foundation of our relationship, and our goal is to contribute to your long-term success in the industry.

Register with us today to experience these unparalleled benefits and embark on a journey of seamless transactions, reliable support, and sustained success.

Sustainability

We’re committed to reducing our environmental footprint. By providing brand-neutral packaging, not only we save resources, cut down CO2 emissions, and minimize material usage, but we empower our customers to reuse the same packaging for shipping. No more swapping duct tape or searching for additional packing materials on your place – just a streamlined process that saves time, money, and the planet.

Additionally, our option for direct shipment to end-users gives quicker solutions without the extra fuss. By cutting out the middle steps, we’re not just saving 1-3 days in delivery time; we’re also slashing costs across the board. Think about it—no need for you, our valued B2B customer, to bring it to your stock, change shipping labels, or deal with the hassle of ordering pickups or trips to the shipping terminal. It’s a cost-effective win-win for both B2B and end-users, making the entire process smoother and more efficient. Fast solutions, lower costs, and a greener approach—now that’s the kind of delivery we can all get behind!

Your data is secure with us, and we’re all about building long-term B2B relationships, focusing on sustainability over short-term gains. Join us in making a positive impact on the environment while enjoying efficient processes.

Certificate of trust

Our company is honored to have received the “Strongest in Lithuania” certificate, an award that recognizes businesses known for their financial stability, timely tax payments, and strong reputation. This certification reflects our core values of trust, transparency, and reliability, which we bring to every partnership. With a proven track record and commitment to integrity, we strive to be a dependable, trustworthy partner for all our clients and collaborators.