CENTAMAX-G 4600

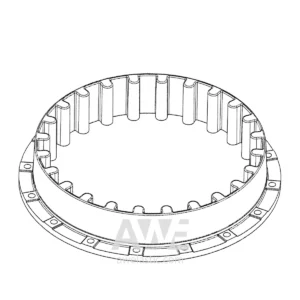

CENTAMAX G 4600 Coupling Elements

CENTAMAX-G Size 4600 – OEM Torsionally Flexible Couplings & SAE Flywheel Adapters

The CENTAMAX-G 4600 series is a heavy-duty torsionally flexible coupling system developed by CENTA Germany for high-power diesel generator sets and industrial drive systems.

Designed for engines in the upper torque range, Size 4600 provides stable torsional behavior, high damping performance, and reliable torque transmission, making it a preferred OEM choice for large gensets, marine auxiliary drives, and industrial machinery operating under demanding load conditions.

Designed for engines in the upper torque range, Size 4600 provides stable torsional behavior, high damping performance, and reliable torque transmission, making it a preferred OEM choice for large gensets, marine auxiliary drives, and industrial machinery operating under demanding load conditions.

This size group includes:

- CENTAMAX-G 4600 elastic elements (NR 50 / 60 / 70 / 72 / 75 Shore)

- Taper-lock bush hubs (typically Type 4545)

- SAE flywheel adapters such as SAE 14 and SAE 18

All components are manufactured according to CENTA’s original design specifications, ensuring mechanical compatibility, correct torsional stiffness, and long service life.

Key Features of CENTAMAX-G 4600

High Torsional Flexibility

The natural-rubber element absorbs torsional vibration peaks and shifts resonances below operating range — reducing stress on generator bearings, crankshafts, and driven equipment.

Backlash-Free Torque Transfer

The interlocked steel outer ring ensures stable, uniform torque transmission without mechanical play.

Taper-Lock Hub System (4545)

The 4600 series uses the Taper-Lock 4545 hub, offering:

- quick installation

- precise shaft centering

- secure clamping

- easy removal for maintenance

This mounting method is widely accepted by generator OEMs due to its reliability and repeatable accuracy.

SAE Flywheel Compatibility

Size 4600 couplings can be paired with OEM flywheel adapters, including:

Each adapter ensures correct centering and bolt-circle alignment between the engine flywheel and the G-4600 elastic element.

Technical Overview – CENTAMAX-G 4600

(Values vary by Shore hardness)

- Nominal Torque (TKN): ~4,600–6,600 Nm

- Maximum Torque (TKmax): ~9,200–17,000 Nm

- Continuous Vibratory Torque (TKW): ~1,840–2,640 Nm

- Maximum Speed: ~2,500–3,000 rpm

- Material: Natural Rubber (NR), black

- Available Shore Options: 50, 60, 70, 72, 75

- Standard Hub: Taper-Lock 4545

These parameters make Size 4600 ideal for high-output engines and generators requiring stable torsional damping and reliable mechanical interface.

Where CENTAMAX-G 4600 Is Used

Size 4600 is widely installed in:

- Industrial generator sets (large kVA range)

- Marine and offshore auxiliary gensets

- Power plant and utility generators

- Large compressors, blowers, and pumping systems

- Heavy industrial machinery with high cyclic torque

CENTA engineered the 4600 series specifically to meet OEM torsional vibration requirements for engines operating in harsh or continuous-duty environments.

Why Choose Original CENTAMAX-G 4600 Components

Only OEM elements deliver:

- correct Shore hardness and stiffness

- matched torsional characteristics validated by TVA

- precise centering and alignment

- safe thermal performance and long service life

- accurate compatibility with SAE adapters and taper hubs

Aftermarket copies often fail to reproduce critical stiffness curves, which can lead to generator instability, bearing overload, or premature coupling failure.

AWELASTIC supplies only new, genuine CENTA Germany components, ensuring proper function and full compatibility.