Read ArticleRead ArticleDiscussion - CENTAMAX couplings are manufactured in several fitment types to suit different...

CENTAX V Elastic Elements – OEM Flexible Couplings for Heavy Mobile & Marine Equipment

Centax V Robust Design and Low Maintenance:

The couplings are conservatively dimensioned with generously sized flexible elements and bearings, ensuring reliability and longevity. They are also maintenance-free, reducing operational hassles.

Efficient Heat Dissipation:

The internal ventilation system prevents overheating during normal operation, ensuring optimal performance and component longevity.

Versatility and Compatibility:

The wide range of design options, along with standard SAE flywheel adaptors and hubs, allows for compatibility with various universal shaft flanges and diverse applications.

Key areas of application for Centax V coupling

- Construction equipment.

- Marine propulsion drives.

- Railway applications.

- Pumps.

Why OEM Centamax Couplings Outperform Copies in Large Gensets

Read ArticleRead ArticleDiscussion - In high-output marine generators, gas power units, locomotives, and heavy...

Common Failure Causes in BoWex® FLE-PA Couplings – What to Watch For and How to Avoid Downtime

Read ArticleRead ArticleDiscussion - When your engine-to-pump connection fails, the coupling is often the first...

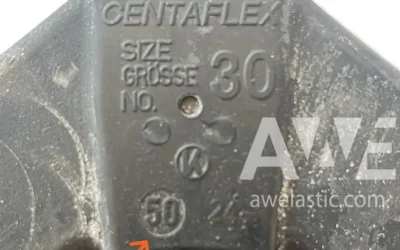

Centaflex A Type 0 and Centaflex A Type 0–S – What is the difference?

Read ArticleRead ArticleDiscussion - Centaflex A Type 0 and Type 0–S – What Is the Difference? When selecting or...

Centaflex Original vs. Copies – What to Look For and Why It Matters

Read ArticleRead ArticleDiscussion - Not all coupling elements are created equal. If you're replacing a worn Centaflex...

Understanding Shore Hardness in Centaflex A Couplings – Why Matching Matters

Read ArticleRead ArticleDiscussion - Understanding Shore Hardness in Centaflex A Couplings – Why Matching Matters When...