Read ArticleRead ArticleDiscussion - CENTAMAX couplings are manufactured in several fitment types to suit different...

John Deere - John Deere Forestry Couplings – Durable Hydraulic Couplings & OEM Replacement Parts

John Deere forestry machines, including harvesters and forwarders, are known for their exceptional quality and efficiency in the industry.

These machines are designed to deliver high performance and productivity in forestry operations.

To maintain this efficiency, timely maintenance using genuine John Deere spare parts is crucial. Regular maintenance ensures that the machines operate at their best, maximizing their lifespan and performance in the field. Using original spare parts also helps in maintaining the reliability and durability of the equipment.

The coupling flange and hub on John Deere forestry machines plays a critical role in connecting the engine with the hydraulic pump. This connection is essential for powering up all necessary equipment and drive motors on the machines. The coupling flange ensures a reliable transfer of power from the engine to the hydraulic system, enabling smooth and efficient operation of the equipment in forestry applications. It is important to ensure that the coupling flange is properly maintained and in good condition to prevent any disruptions in power transmission. If you have specific questions about the coupling flange or its maintenance

Why OEM Centamax Couplings Outperform Copies in Large Gensets

Read ArticleRead ArticleDiscussion - In high-output marine generators, gas power units, locomotives, and heavy...

Common Failure Causes in BoWex® FLE-PA Couplings – What to Watch For and How to Avoid Downtime

Read ArticleRead ArticleDiscussion - When your engine-to-pump connection fails, the coupling is often the first...

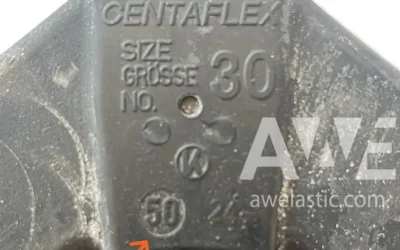

Centaflex A Type 0 and Centaflex A Type 0–S – What is the difference?

Read ArticleRead ArticleDiscussion - Centaflex A Type 0 and Type 0–S – What Is the Difference? When selecting or...

Centaflex Original vs. Copies – What to Look For and Why It Matters

Read ArticleRead ArticleDiscussion - Not all coupling elements are created equal. If you're replacing a worn Centaflex...

Understanding Shore Hardness in Centaflex A Couplings – Why Matching Matters

Read ArticleRead ArticleDiscussion - Understanding Shore Hardness in Centaflex A Couplings – Why Matching Matters When...