Read ArticleRead ArticleDiscussion - CENTAMAX couplings are manufactured in several fitment types to suit different...

CENTAFLEX H OEM Couplings – Flexible Power Transmission for Construction & Agricultural Machinery

CENTAFLEX-H Torsionally Stiff Coupling for Diesel-Hydraulic Drives

CENTAFLEX-H coupling is engineered for high-performance, resonance-free operation in diesel-hydraulic drive systems. Its robust design features a heavy-duty elastomer element with integrated aluminum or steel bushes, delivering exceptional torsional stiffness while effectively damping vibrations and shocks. This compact coupling accommodates significant axial and moderate radial and angular misalignments, ensuring smooth power transmission. Resistant to oil and capable of withstanding extreme temperatures, the CENTAFLEX-H is both durable and maintenance-free.

Key Features:

Easy Installation: Designed for blind assembly, reducing mounting effort and time.

Applications:

KOMATSU

HITACHI

HYUNDAI

KOBELCO

DOOSAN

VOLVO

CASE

JCB

YANMAR

Often found with DEUTZ and PERKINS engines

Why OEM Centamax Couplings Outperform Copies in Large Gensets

Read ArticleRead ArticleDiscussion - In high-output marine generators, gas power units, locomotives, and heavy...

Common Failure Causes in BoWex® FLE-PA Couplings – What to Watch For and How to Avoid Downtime

Read ArticleRead ArticleDiscussion - When your engine-to-pump connection fails, the coupling is often the first...

Centaflex A Type 0 and Centaflex A Type 0–S – What is the difference?

Read ArticleRead ArticleDiscussion - Centaflex A Type 0 and Type 0–S – What Is the Difference? When selecting or...

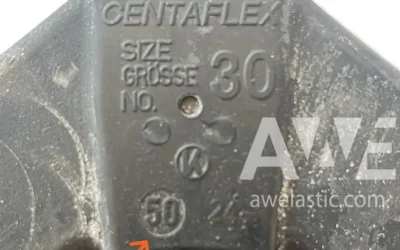

Centaflex Original vs. Copies – What to Look For and Why It Matters

Read ArticleRead ArticleDiscussion - Not all coupling elements are created equal. If you're replacing a worn Centaflex...

Understanding Shore Hardness in Centaflex A Couplings – Why Matching Matters

Read ArticleRead ArticleDiscussion - Understanding Shore Hardness in Centaflex A Couplings – Why Matching Matters When...