65 FLE-PA

BoWex® 65 FLE-PA Coupling

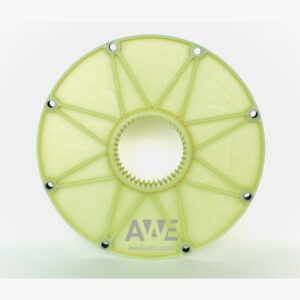

BoWex® 65 FLE-PA Coupling – Original KTR Curved-Tooth Coupling (42 Teeth)

The BoWex 65 FLE-PA is a torsionally stiff curved-tooth

coupling developed by KTR-Kupplungstechnik for diesel engine pump drives, mobile machinery, generator sets, and marine auxiliaries.

This model is defined by its 42 internal teeth, a key identification features unique to the 65 FLE-PA size. Technicians frequently use tooth count to verify correct fitment — and 42 teeth always indicate Size 65.

This model is defined by its 42 internal teeth, a key identification features unique to the 65 FLE-PA size. Technicians frequently use tooth count to verify correct fitment — and 42 teeth always indicate Size 65.

The coupling housing is made from >PA6-GF25< high-strength polyamide reinforced with glass fiber, while the steel hub ensures precise torque transfer and long-term durability.

All genuine elements are marked with:

KTR, BoWex, FLE-PA, >PA6-GF25<, D-4440 Rheine — confirming OEM origin and material specification.

All genuine elements are marked with:

KTR, BoWex, FLE-PA, >PA6-GF25<, D-4440 Rheine — confirming OEM origin and material specification.

Technical Specifications – BoWex 65 FLE-PA

- Internal teeth: 42 (Size 65 identifier)

- Nominal torque (TKN): 650 Nm

- Maximum torque (TKmax): 1,600 Nm

- Compatible flywheel standards: SAE 8, SAE 10, SAE 11.5

- Material: Polyamide PA6-GF25 with steel mating components

- Design style: Torsionally stiff, backlash-free curved-tooth coupling

- Operating principle: Dry-running, maintenance-free

- Typical applications: Construction machinery, hydraulic pump drives, industrial gensets.

Why the 42-Tooth Design Matters for Size 65

The BoWex 65 FLE-PA can be quickly identified by its 42-tooth polyamide ring.

This geometry ensures:

This geometry ensures:

- accurate centering on the hub

- correct engagement depth

- uniform load distribution

- long service life under shock loads and rapid torque changes

Using an element with the wrong tooth count leads to misalignment, noise, premature wear, and—in severe cases—pump shaft or flywheel damage.

Where the BoWex 65 FLE-PA Is Commonly Installed

Size 65 sits in the mid-range torque class of BoWex FLE-PA couplings and is widely used in:

- Excavators, loaders, and forestry machinery

- Hydraulic power packs and pump drives

- Compact diesel generator sets

- Marine auxiliary engines

- Industrial mobile power equipment

Its torsionally stiff behavior is ideal for machines where precise torque transfer and stable shaft alignment are essential.

Why Only Original KTR BoWex 65 FLE-PA Should Be Used

Non-OEM copies may look similar, but they rarely match the:

- exact polyamide mixture PA6-GF25

- tooth geometry and centering tolerances

- torsional stiffness required by pump and diesel engine manufacturers

- dimensional accuracy needed for SAE compliance

Even though non-original parts may save ~€100, the risk of:

- tooth breakage

- misalignment damage

- increased vibration

- early coupling failure

is not acceptable on machinery valued above €100k

Only authentic KTR BoWex 65 FLE-PA ensures safe operation, predictable stiffness, and full compatibility with OEM equipment.