Read Article Read Article Discussion - Centaflex-D.B.P-2019608-JAP.Pat-778322 Centaflex-D.B.P-2019608-JAP.Pat-778322...

Compressor couplings - Mobile and stationary compressor couplings. NEW, Original. Available on stock for worldwide delivery

Compressor Couplings – OEM Solutions for Stationary and Mobile Compressors

Compressor couplings play a critical role in ensuring reliable power transmission, vibration damping, and long service life. Depending on the compressor type — stationary or mobile — different coupling designs are required to handle alignment, torque transfer, and torsional vibrations.

Stationary Compressors – Electric Motor Drives

In stationary compressors, typically powered by electric motors, the most common solution is the ROTEX® type coupling. These use two metallic hubs and a central elastomer spider to provide:

- Compact design with easy installation

- Reliable torque transfer for continuous duty

- Good misalignment compensation

- Minimal maintenance requirements

ROTEX couplings are a trusted standard in industrial compressors where stable and efficient performance is required.

Mobile Compressors – Diesel Engine Drives

Mobile compressors are driven by diesel engines, which produce significant torsional vibrations. To protect the drivetrain, torsionally flexible couplings are essential.

In this case, solutions like:

- BoWex® Elastic couplings

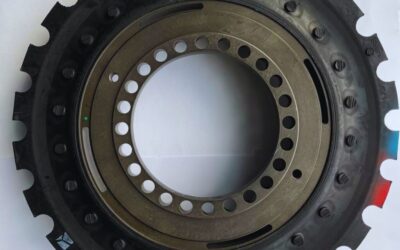

- CENTAFLEX® rubber elements

…are used to compensate for misalignment, vibrations, and shock loads. These flexible elements ensure smooth operation and help extend the lifespan of the entire compressor system.

Leading OEM Manufacturers

Trusted producers such as CENTA, KTR, Rexnord and Stromag offer dedicated compressor coupling solutions. Each coupling is preselected and carefully calculated for the specific engine or motor setup, ensuring:

- Optimal damping performance

- Maximum longevity under heavy load conditions

- Safe and reliable operation in both stationary and mobile environments

Why Choose Original OEM Compressor Couplings?

If your compressor was originally equipped with a coupling from KTR, CENTA, Rexnord or Stromag, it is always best to use the same OEM element for replacement. Original couplings guarantee:

- Stable, predictable performance

- Correct Shore hardness and torsional stiffness

- Compatibility with existing hubs and bolts

- Proven reliability in demanding compressor applications

📩 Need a replacement or identification help?

Send us your coupling markings, part number, or a photo of the worn element — our team will verify it and provide the correct OEM compressor coupling from stock, ready for fast worldwide delivery.

CENTAMAX Coupling Performance – Understanding Shore Hardness and Its Impact

Read ArticleRead ArticleDiscussion - Shore hardness is a key factor in determining the performance of elastomeric...

Centamax couplings: Choosing original parts over aftermarket alternatives.

To deepen the understanding of CentaMax couplings and their significance in industrial applications, it is essential to focus on the intricacies of their design, the precision engineering involved, and the impact of choosing original parts over aftermarket alternatives.

Centamax Couplings: Enhancing Power Transmission and Durability in Demanding Industrial Applications

Centamax couplings are high-performance, torsionally flexible couplings designed for demanding industrial applications where reliability, durability, and efficient power transmission are critical.

How to identify Centaflex H coupling?

Centaflex H couplings usually consist of plastic element and aluminum inserts. In most cases it is enough to replace only plastic element. If there are damaged aluminum inserts, they can be replaced as well.

How to identify Centamax coupling?

To identify correctly Centamax element there are several possible options. Method 1: Using Description or drawing number. You may find complete description or drawing number from documentation of your machinery.