Read Article

0

Read Article

Discussion –

0

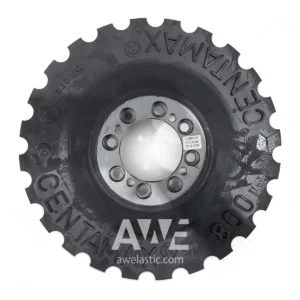

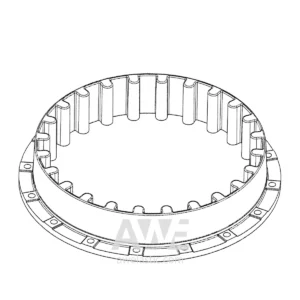

Why OEM Centamax Couplings Outperform Copies in Large Gensets

In high-output marine generators, gas power units, locomotives, and heavy equipment, the coupling element is more than just a connector — it’s a critical vibration damping and torque transfer component that keeps your powertrain healthy.

For operators of large CAT, Cummins, MAN, MTU, Wartsilla, Deutz powered gensets and other high-torque systems, the choice between OEM CENTAMAX couplings and aftermarket copies can have major cost, reliability, and safety implications.

The Hidden Costs of Cheap Coupling Copies

Aftermarket or “compatible” couplings may look similar to genuine CENTAMAX products, but in critical performance areas, they often fall short:

- Inconsistent Shore hardness → results in incorrect torsional stiffness and higher vibration levels.

- Lower-quality rubber compounds → degrade faster under heat and oil exposure.

- Poor manufacturing tolerances → lead to misalignment, uneven load distribution, and premature bolt loosening.

- Unverified torque ratings → copies rarely undergo the same OEM stress and fatigue testing.

In large gensets, a failed coupling doesn’t just stop power production — it can damage the flywheel, bearings, or crankshaft, resulting in weeks of downtime.

Why OEM CENTAMAX Couplings are Different

Genuine CENTAMAX elements are:

- Manufactured to exact OEM specs with precise fitment.

- Material-tested for heat resistance, oil resistance, and long-term elasticity.

- Shore hardness matched to the application for optimal vibration damping.

- Selected, calculated, approved and used by engine manufacturers, including Caterpillar, Deutz, MAN, Cummins, MTU, Wartsilla for large marine and industrial engines.

Performance in Large Gensets: A Critical Difference

Large marine and gas generators face:

- Constant load cycling

- Thermal expansion from high operating temperatures

- Strong torsional pulses from large displacement engines

OEM CENTAMAX couplings handle these conditions predictably and reliably, preserving drivetrain integrity and reducing operator intervention.

In contrast, aftermarket couplings may harden, crack, or deform in less than half the OEM service life.

Long-Term Savings with OEM

While the upfront price of a genuine CENTAMAX coupling is higher than a copy, the total cost of ownership is far lower:

- Fewer replacements over the life of the engine

- Reduced risk of catastrophic drivetrain damage

- No unplanned downtime due to premature coupling failure

AWELASTIC: Your Trusted OEM Supplier

We supply only new, original CENTAMAX couplings — including the CM-18000 — with:

- All Shore hardness options

- Express and standard options of worldwide shipping

- Proven reliability in marine, powergen, and heavy equipment sectors

CENTAMAX – OEM Coupling Elements, In Stock

- No aftermarket compromises

- OEM-certified performance

- Fast global delivery

Keywords : OEM vs aftermarket coupling, generator coupling reliability, CENTAMAX original parts, CAT engine coupling, CM-18000 performance.

Centamax Couplings

You May Also Like

Understanding CENTAMAX Coupling Types – SB, SBE, SC, and SCE

Read ArticleRead ArticleDiscussion - CENTAMAX couplings are manufactured in several fitment types to suit different...

Common Failure Causes in BoWex® FLE-PA Couplings – What to Watch For and How to Avoid Downtime

Read ArticleRead ArticleDiscussion - When your engine-to-pump connection fails, the coupling is often the first...

Centaflex A Type 0 and Centaflex A Type 0–S – What is the difference?

Read ArticleRead ArticleDiscussion - Centaflex A Type 0 and Type 0–S – What Is the Difference? When selecting or...