Read ArticleRead ArticleDiscussion - CENTAMAX couplings are manufactured in several fitment types to suit different...

Centamax

CENTAMAX Couplings for Marine, Powergen & Heavy Equipment – Original. In Stock. Ready to Ship

CENTAMAX Couplings for Marine, Powergen & Heavy Equipment – Original. In Stock. Ready to Ship.

Centamax Coupling – The Ultimate Marine, Rail and Industrial Solution

The Centamax coupling is engineered for maximum durability, efficiency, and reliability, making it an ideal choice for marine, railway and industrial applications. Developed in close collaboration with engine and equipment manufacturers, including Wärtsilä and CAT, Centamax ensures seamless integration and performance excellence.

Key Features and Benefits:

Superior Durability: Designed with high-quality materials, Centamax couplings withstand extreme conditions, providing long-lasting performance.

Optimized Efficiency: With high torsional flexibility, these couplings reduce vibrations, ensuring smooth and efficient power transmission.

High-Quality Engineering: Manufactured with original OEM standards, guaranteeing reliability in critical applications.

Advanced Ventilation: The HTC (High Thermal Capacity) design allows for superior power loss dissipation, making it possible to use smaller, cost-effective coupling sizes.

Fail-Safe Design: Available with an optional fail-safe device, preventing system failures in case of overload.

Wide Temperature Range: Suitable for demanding environments with temperature ranges from -45°C to +120°C, depending on material selection (NR, Si, or CENTALAN HT).

Versatile Applications: Ideal for marine propulsion couplings, shaft couplings, and power transmission in industrial and marine settings.

Designed for Excellence

Centamax couplings provide resonance-free operation, shifting critical vibrations below operational speed, thus reducing stress on connected components. The product line includes various types such as Centamax-S, Centamax-G, Centamax-HTC, and Centamax-B, each tailored for specific applications.

Trusted by Industry Leaders

As a preferred choice for marine coupling solutions, Centamax is trusted by engine producers like Wärtsilä and CAT, ensuring compatibility and superior performance in demanding environments.

Centamax coupling catalogue - Dimensions, performance data, selection information you are able to find on Downloads section.

Not sure about correct selection? - CENTAMAX Coupling identification

We are here to help you - Whatsapp, hello@aweltagroup.com

read more

Why OEM Centamax Couplings Outperform Copies in Large Gensets

Read ArticleRead ArticleDiscussion - In high-output marine generators, gas power units, locomotives, and heavy...

Common Failure Causes in BoWex® FLE-PA Couplings – What to Watch For and How to Avoid Downtime

Read ArticleRead ArticleDiscussion - When your engine-to-pump connection fails, the coupling is often the first...

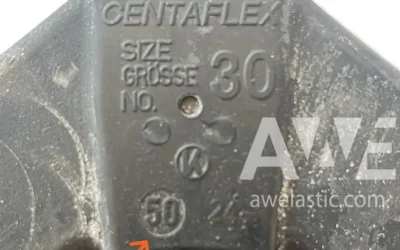

Centaflex A Type 0 and Centaflex A Type 0–S – What is the difference?

Read ArticleRead ArticleDiscussion - Centaflex A Type 0 and Type 0–S – What Is the Difference? When selecting or...

Centaflex Original vs. Copies – What to Look For and Why It Matters

Read ArticleRead ArticleDiscussion - Not all coupling elements are created equal. If you're replacing a worn Centaflex...

Understanding Shore Hardness in Centaflex A Couplings – Why Matching Matters

Read ArticleRead ArticleDiscussion - Understanding Shore Hardness in Centaflex A Couplings – Why Matching Matters When...